Discover more products in the cutting wire category

Loop- type Diamond Wire Saw

To Cut Hard & Brittle Materials

$30

Discover more products in the Graphite category

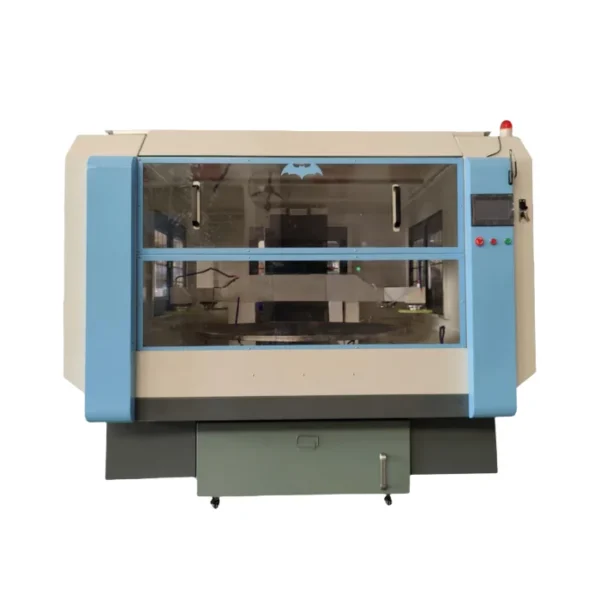

CNC Graphite Diamond Wire Saw

Fast, Smooh, and Precise!

$18000

Discover more products in the optical glass category

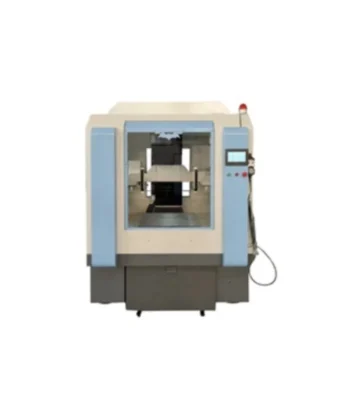

Single Diamond Wire Cutting Equipment

Replace

Inside Slicer

$14000

Our categories

Lots of new products and product collections

Sic Cut

5 products

Metal Cut

5 products

Silicon Cut

9 products

Optics Cut

10 products

Graphite Cut

9 products

Cutting Wire

13 products

Gemstone Cut

7 products

Glass Cut

10 products

Alumia Cut

7 products

Quartz Cut

10 products

Diamond Wire Saw bestsellers

$680.00

Select options

This product has multiple variants. The options may be chosen on the product page

Product Collections

Explore product collections from all kinds of diamond wire saw machines

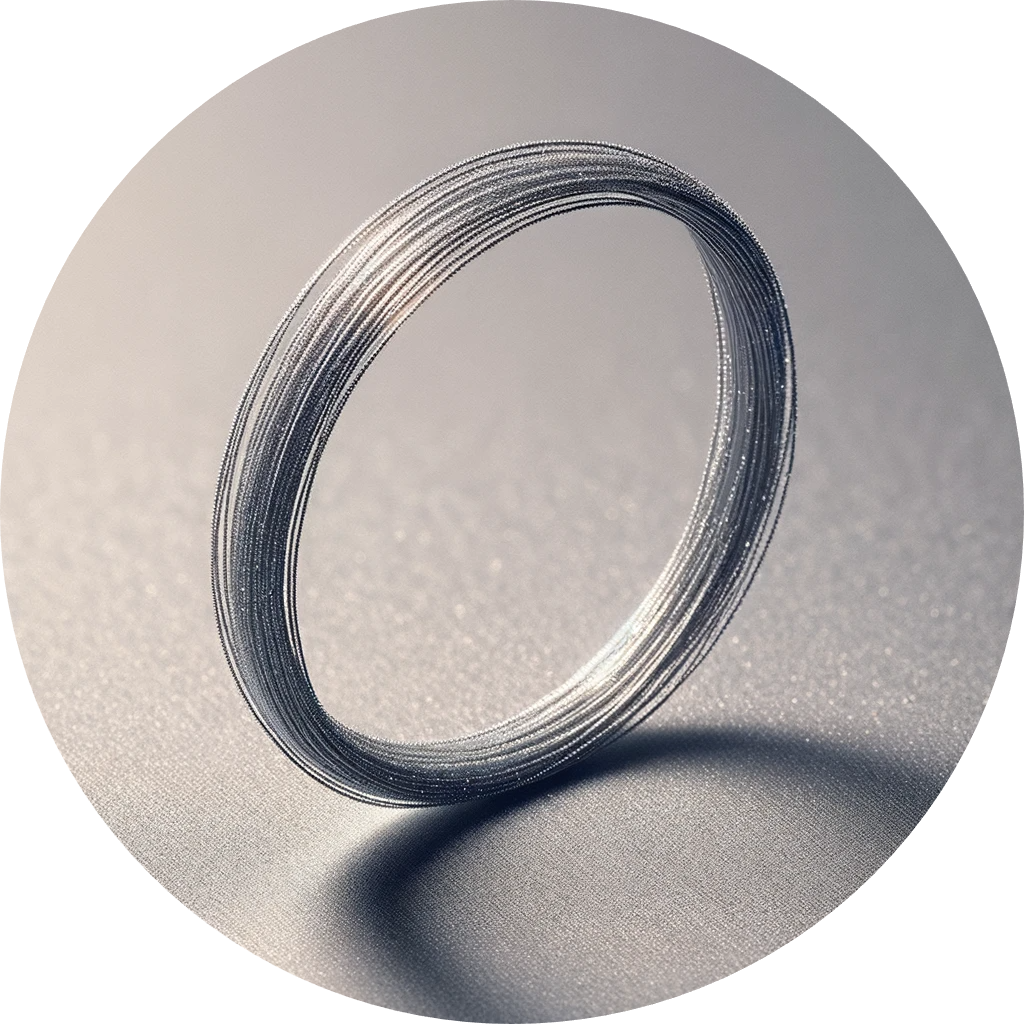

840 mm Endless Diamond Wire Loop

$35.00

These closed-loop wires are fully coated with high-quality synthetic diamond particles, providing exceptional cutting efficiency and an extended lifespan.

Diamond Wire Saw for Quartz SH60-R

$1.00

This is a medium-sized horizontal cutting machine, also known as a Diamond Wire Saw for cutting quartz, optical glass, industrial ceramics, silicon rods, and more. The diamond wire moves parallel to the ground while simultaneously moving forward, backward, upward, and downward to cut the workpiece. The workpiece is fixed on the material table, which can remain stationary or rotate as needed.

840 mm Endless Diamond Wire Loop

$35.00

These closed-loop wires are fully coated with high-quality synthetic diamond particles, providing exceptional cutting efficiency and an extended lifespan.

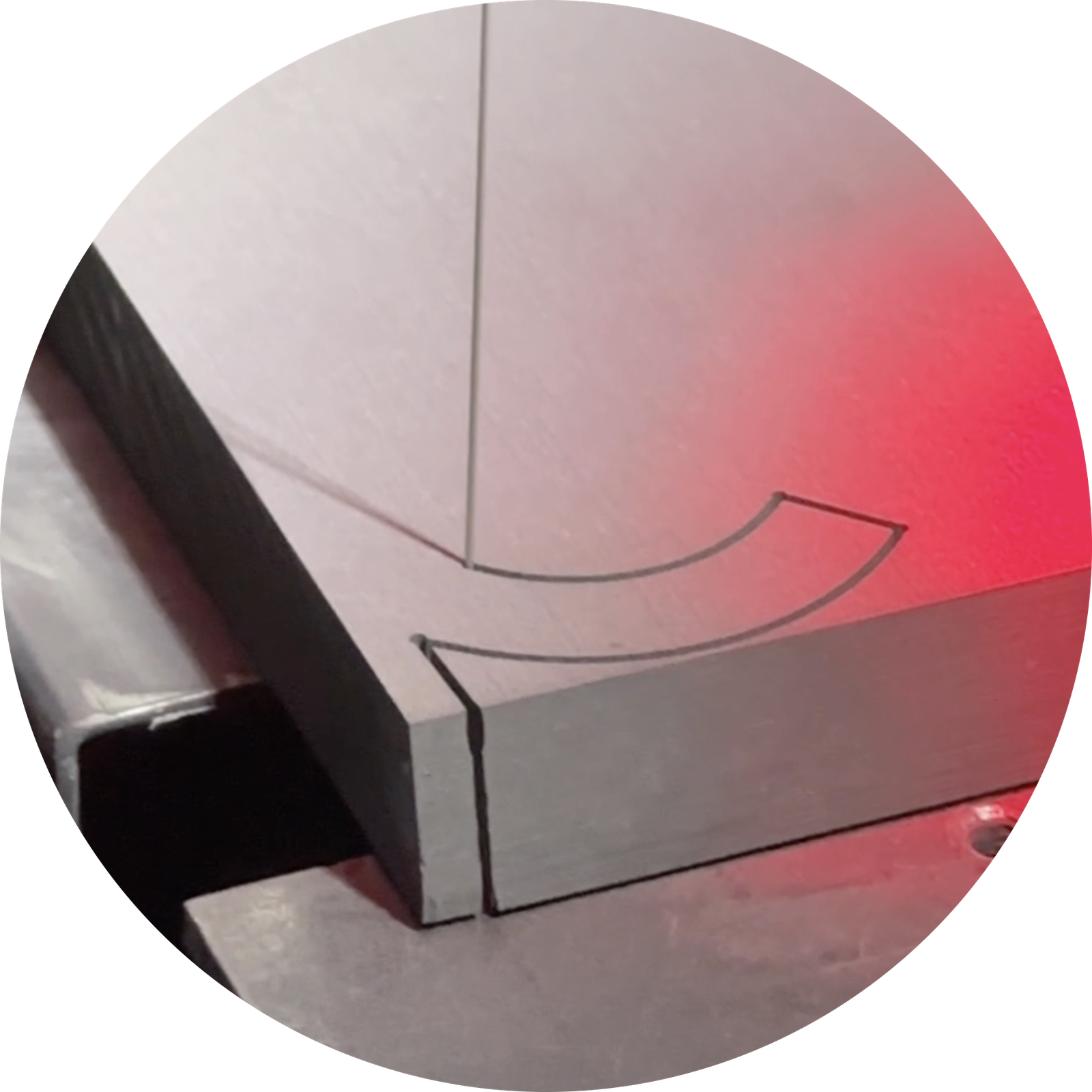

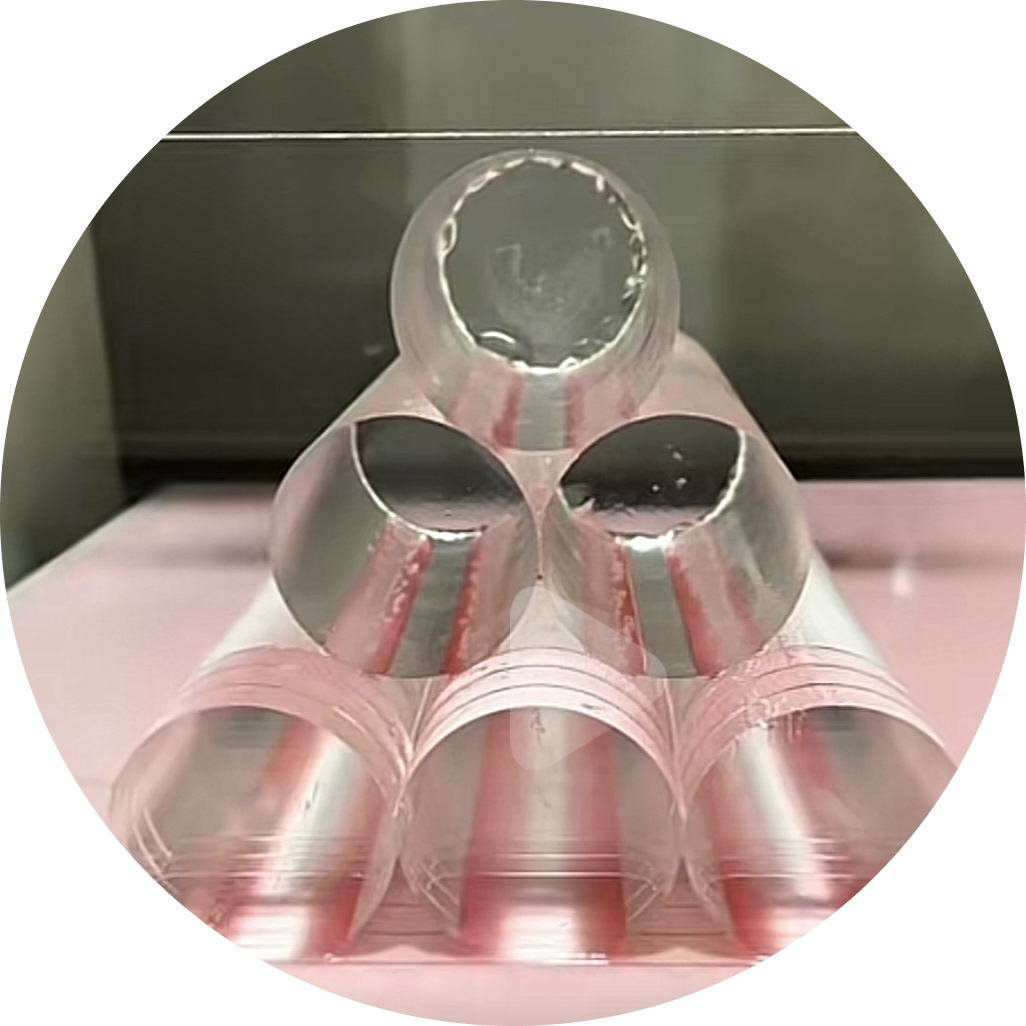

Optical Glass Cutting Wire Saw SG 20

$1.00

This gantry-style cutting machine uses a closed-loop diamond wire to cut materials with hardness lower than diamond. It is capable of large-scale slicing and is widely used in the optoelectronics industry, earning it the name Optical Glass Cutting Wire Saw. With its high cutting precision and cutting efficiency 3 to 4 times greater than inner-diameter slicing machines, it has rapidly replaced traditional inner-diameter slicing equipment.

Segment Coated Diamond Wire Loop

$1.00

The segmented coated diamond wire is a cutting-edge innovation in diamond wire technology, designed to optimize cutting efficiency and durability. Unlike fully coated wires, this wire features segmented diamond coating along its length, strategically placed to enhance performance and reduce wear.

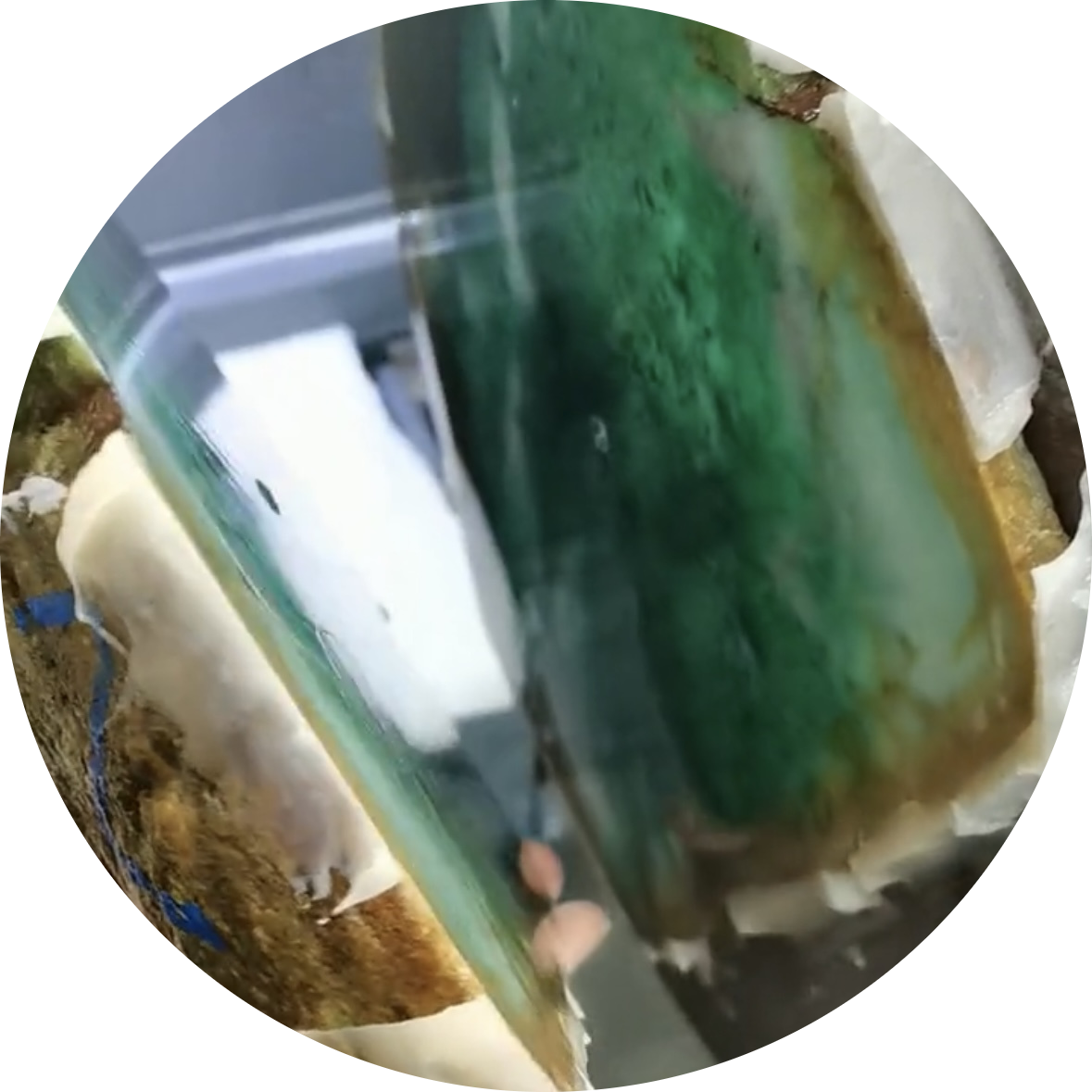

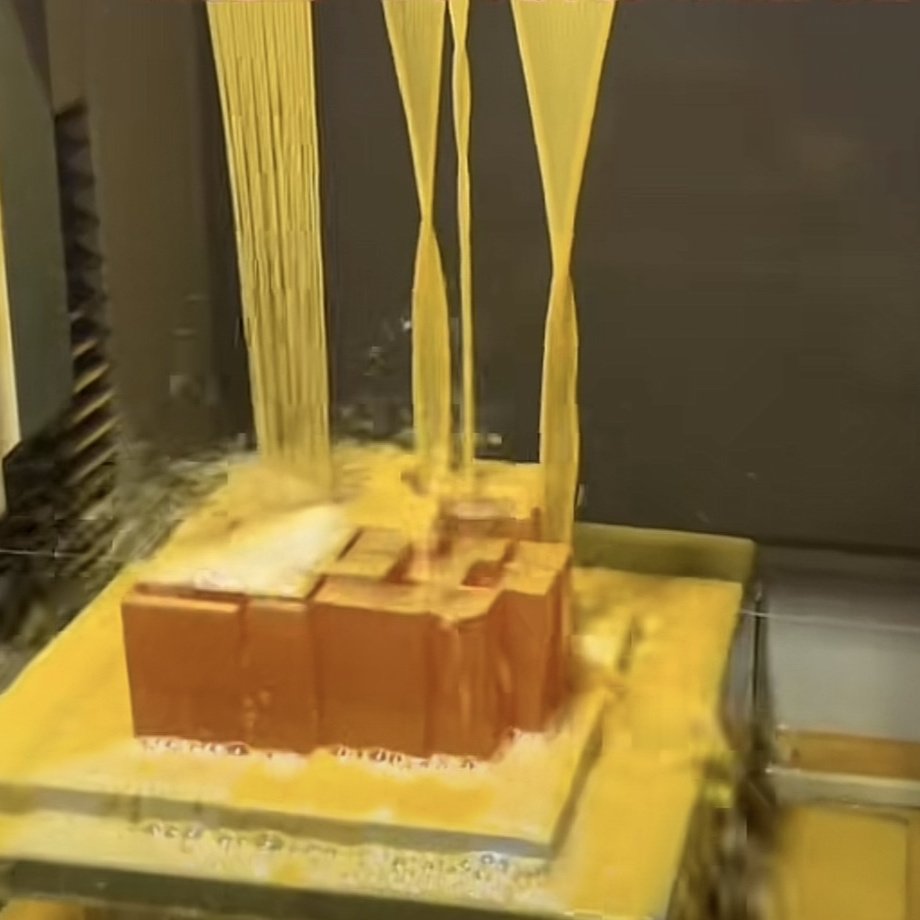

Graphite Cut Machine SVI 60-60

$1.00

This is a multi-functional CNC wire cutting machine designed to handle a variety of tasks, including automatic material cutting, slicing, external shape cutting, internal shape cutting, and, when used with specialized fixtures, cutting tapered products. Its versatility makes it suitable for a wide range of applications.

Glass Wire Saw Machine SG 40

$1.00

This gantry-style cutting machine uses a closed-loop diamond wire to cut materials with hardness lower than diamond. It is designed for large-scale slicing and is widely used in the optoelectronics industry, commonly referred to as the Glass Wire Saw Machine. The machine allows materials to be stacked for simultaneous cutting of multiple workpieces, ensuring exceptionally high cutting efficiency.

840 mm Endless Diamond Wire Loop

$35.00

These closed-loop wires are fully coated with high-quality synthetic diamond particles, providing exceptional cutting efficiency and an extended lifespan.

840 mm Endless Diamond Wire Loop

$35.00

These closed-loop wires are fully coated with high-quality synthetic diamond particles, providing exceptional cutting efficiency and an extended lifespan.

Diamond Wire Cutting Machine SVI 50-50

$1.00

The Diamond Wire Cutting Machine is an advanced cutting solution designed for precise and efficient material shaping. Equipped with an automatic 90-degree rotation system, this machine can easily transform materials into square shapes. Utilizing a closed-loop diamond wire as the cutting tool, it ensures high precision, smooth surfaces, and minimal material waste.

Table Top Diamond Wire Saw SGD 52

$1.00

This is a desktop-sized wire cutting machine that uses a closed-loop diamond wire as the cutting tool. It is easy to operate, highly precise, and delivers smooth cutting surfaces. Its compact design makes it ideal for laboratory cutting tasks and hobbyist applications.

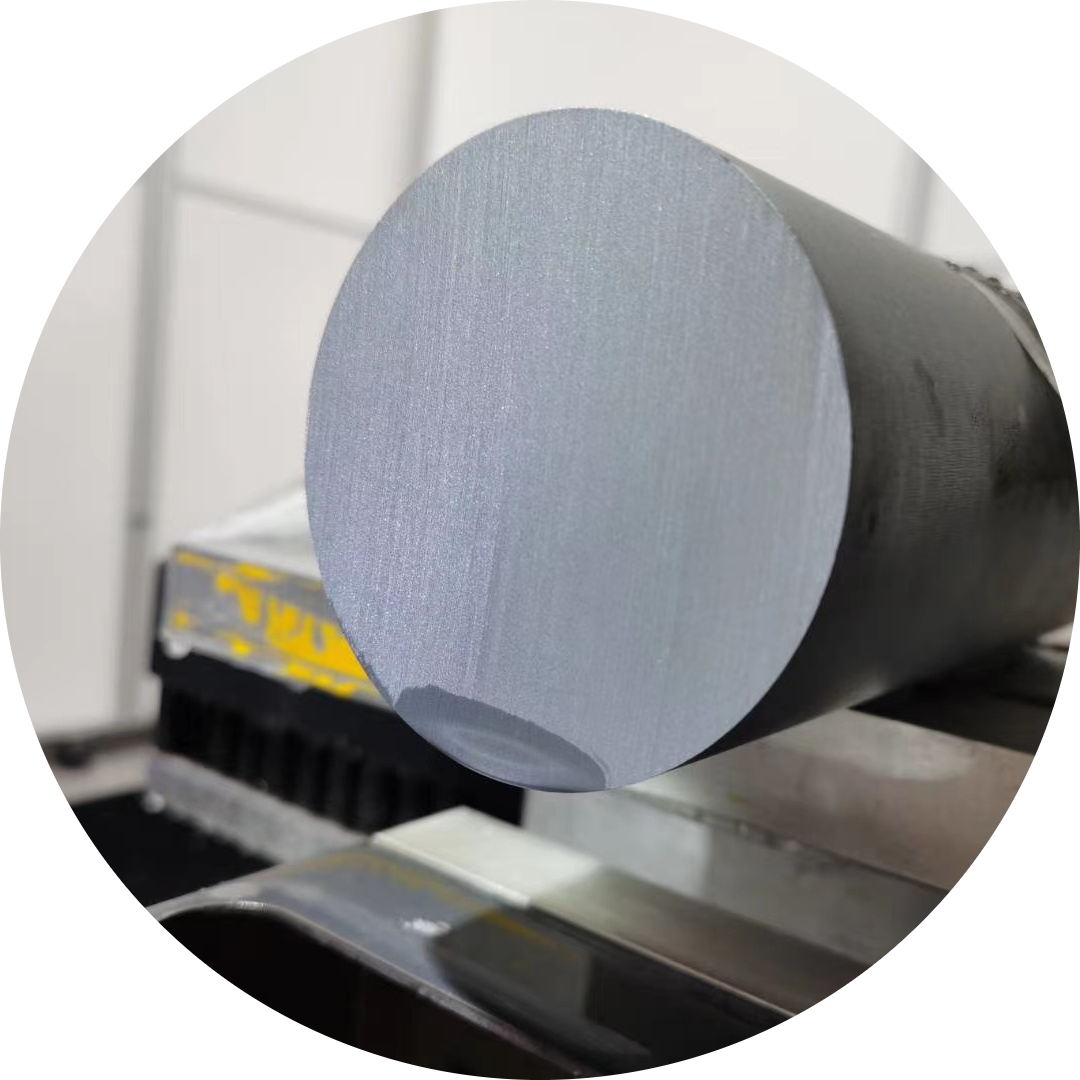

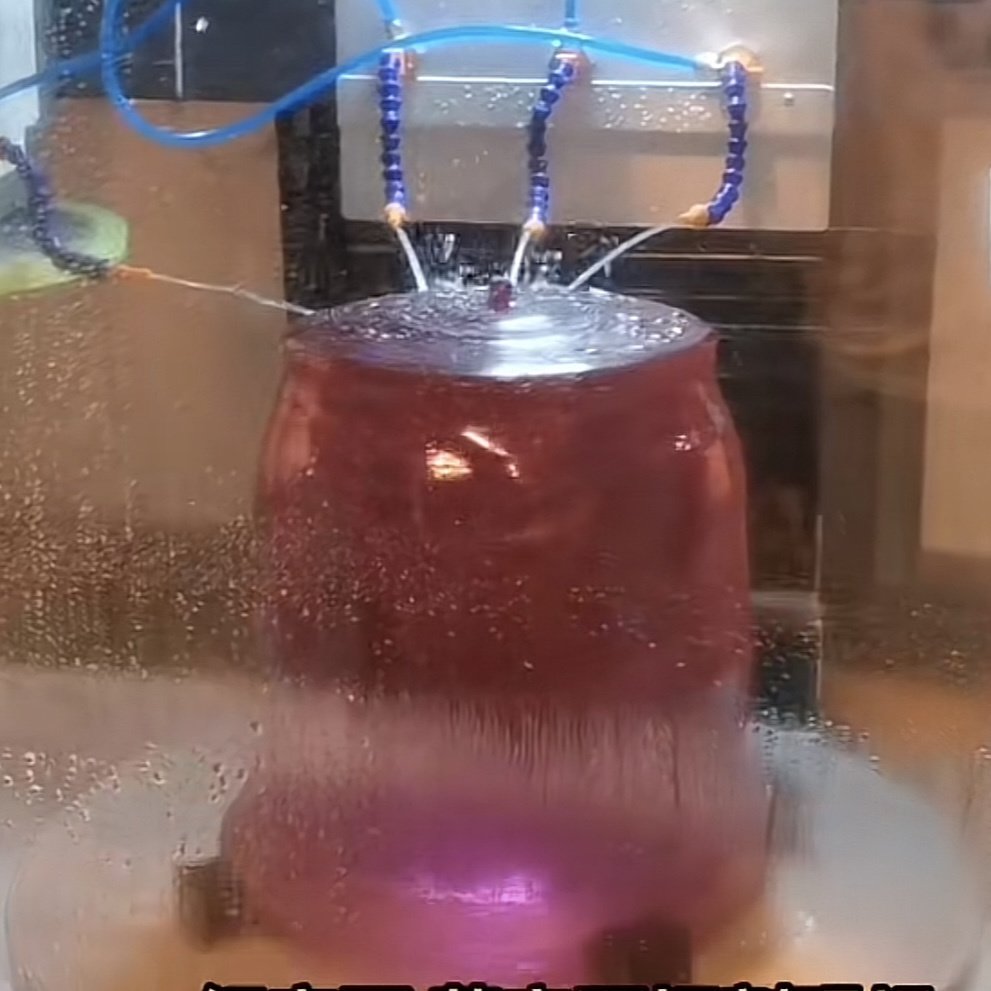

Endless Diamond Wire Saw SH150-R

$1.00

This is an Endless Diamond Wire Saw, a large-scale horizontal cutting machine capable of cutting workpieces with a diameter of up to 1.5 meters. The cutting tool is a closed-loop diamond wire that runs at high speed in a single direction, making it extremely sharp and particularly suited for cutting large workpieces. Our customers commonly use it to cut large quartz, alumina, optical glass, germanium single crystals, and other similar materials.

840 mm Endless Diamond Wire Loop

$35.00

These closed-loop wires are fully coated with high-quality synthetic diamond particles, providing exceptional cutting efficiency and an extended lifespan.

Endless Diamond Wire Saw SGR 40

This is a loop wire cutting machine designed for versatile cutting tasks. It can automatically slice materials, rotate the loading table to cut square blocks, or adjust to freely set angles for cutting prisms. With its advanced automation and flexibility, it is an ideal solution for precise and efficient cutting applications.

840 mm Endless Diamond Wire Loop

$35.00

These closed-loop wires are fully coated with high-quality synthetic diamond particles, providing exceptional cutting efficiency and an extended lifespan.

Wire Cutting Machine for Graphite SVI 80-80

The Wire Cutting Machine for Graphite SVI80 is a versatile cutting solution designed for both slicing and contouring graphite and other brittle materials. With advanced features such as remote operation and maintenance, the SVI80 empowers manufacturers worldwide with seamless, efficient, and precise cutting performance.

Segment Coated Diamond Wire Loop

$1.00

The segmented coated diamond wire is a cutting-edge innovation in diamond wire technology, designed to optimize cutting efficiency and durability. Unlike fully coated wires, this wire features segmented diamond coating along its length, strategically placed to enhance performance and reduce wear.

New Diamond Wire Saw of This Quarter

The diamond wire saw machines newly designed in this quarter

840 mm Endless Diamond Wire Loop

$35.00

These closed-loop wires are fully coated with high-quality synthetic diamond particles, providing exceptional cutting efficiency and an extended lifespan.

Diamond Wire Cutting Machine SVI 50-50

$1.00

The Diamond Wire Cutting Machine is an advanced cutting solution designed for precise and efficient material shaping. Equipped with an automatic 90-degree rotation system, this machine can easily transform materials into square shapes. Utilizing a closed-loop diamond wire as the cutting tool, it ensures high precision, smooth surfaces, and minimal material waste.

Optical Glass Cutting Wire Saw SG 20

$1.00

This gantry-style cutting machine uses a closed-loop diamond wire to cut materials with hardness lower than diamond. It is capable of large-scale slicing and is widely used in the optoelectronics industry, earning it the name Optical Glass Cutting Wire Saw. With its high cutting precision and cutting efficiency 3 to 4 times greater than inner-diameter slicing machines, it has rapidly replaced traditional inner-diameter slicing equipment.

Rules for choosing diamond wire saw

When selecting the right diamond wire cutting equipment, consider the following points:

-

Ensure the machine size matches the dimensions of the primary materials to be cut. An oversized machine may reduce cutting precision.

-

For hard materials, opt for wet cutting equipment with a water circulation system.

-

If you have specific requirements, such as cutting at a particular angle, feel free to consult us for customization.

-

Many equipment models may not be updated in a timely manner, so please contact us for assistance in choosing the most suitable model.

Latest articles

CNC Diamond Saw: Precision Cutting for the Semiconductor Industry

The semiconductor industry is built on precision, innovation,...

Key Features of Endless Diamond Wire Cutting Equipment:

Endless Wire Design:

- Utilizes a closed-loop diamond wire, typically less than 10 meters in length, which is significantly shorter compared to traditional diamond wire cutting machines (wire lengths exceeding 1000 meters).

- The endless design eliminates the need for frequent wire changes, improving operational efficiency.

High-Speed Wire Operation:

- The diamond wire operates at speeds of up to 80 meters/second, enabling fast cutting.

- High-speed operation ensures superior surface smoothness, eliminating or significantly reducing wire marks.

Wide Range of Applications:

- Suitable for cutting hard and brittle materials such as silicon, graphite, sapphire, quartz, alumina ceramics, silicon carbide, silicon nitride, and boron nitride.

- Especially effective for non-conductive materials (e.g., graphite) that cannot be processed using traditional EDM cutting techniques.

Exceptional Cutting Quality:

- Produces smooth cutting surfaces, often eliminating the need for additional polishing.

- Reduces material waste, which is particularly beneficial when working with expensive materials.

Eco-Friendly Operation:

- Can use water cooling or eco-friendly cooling liquids to minimize heat buildup and reduce dust emissions during cutting.

Application Fields:

- Semiconductors: Cutting silicon wafers, sapphire substrates, quartz substrates, etc.

- Optics: Processing optical glass, lens materials, and other precision optical components.

- Renewable Energy: Cutting solar crystalline silicon and battery materials.

- Aerospace: Precision machining of high-hardness ceramics and composite materials.

- Other Industries: Precision machining of electronic ceramics, graphite molds, and more.

Comparison to Traditional Diamond Wire Cutting Machines:

- Endless diamond wire machines feature shorter, more stable wires with higher operating speeds, making them ideal for precision applications.

- No need to alternate the wire's running direction, simplifying the mechanical structure and reducing maintenance costs.

If you'd like more detailed information or strategies to promote and sell this type of equipment, I’d be happy to assist further!