The world is entering a new era of connectivity, driven by advancements in 5G technology and the growing adoption of the Internet of Things (IoT). These innovations rely on cutting-edge components that demand precision, reliability, and efficiency in their production. As manufacturers work to meet the increasing demand for 5G devices and IoT components, diamond wire cutting technology is playing an increasingly important role in enabling high-quality, scalable manufacturing processes.

In this article, we’ll explore how VIMFUN’s diamond wire cutting solutions are shaping the production of critical components for 5G and IoT technologies, helping manufacturers meet the challenges of this rapidly evolving landscape.

The Rising Demand for Precision in 5G and IoT Manufacturing

Both 5G networks and IoT devices depend on a range of advanced materials and components, including semiconductor wafers, sapphire substrates, and high-performance ceramics. These materials are critical for applications such as:

- 5G antennas: High-frequency antennas require precision-cut substrates to ensure optimal performance.

- IoT sensors: Miniaturized sensors rely on exact tolerances to function effectively in diverse environments.

- Power electronics: Materials like silicon carbide (SiC) are used in 5G base stations and IoT power systems, demanding precise and efficient cutting techniques.

The production of these components requires a high degree of accuracy to maintain the performance, reliability, and efficiency needed for their respective applications. This is where diamond wire cutting technology becomes indispensable.

How Diamond Wire Cutting Supports 5G and IoT Manufacturing

1. Precision for High-Frequency Components

5G and IoT technologies operate at extremely high frequencies, which makes the precision of components like substrates and wafers critical. Even minor imperfections in these components can lead to signal degradation or reduced efficiency.

VIMFUN’s diamond wire cutting machines are engineered to achieve micron-level precision, ensuring that materials such as sapphire and quartz are cut with smooth surfaces and tight tolerances. This precision helps manufacturers meet the exacting standards required for 5G and IoT components, reducing defects and improving overall performance.

2. Efficiency in High-Volume Production

The rapid growth of 5G and IoT markets has led to a surge in demand for components, putting pressure on manufacturers to scale production without compromising quality. Traditional cutting methods, such as mechanical sawing or laser cutting, often struggle to meet these demands due to slower speeds and higher material waste.

With diamond wire cutting technology, manufacturers can achieve faster cutting speeds and higher throughput while maintaining precision. The continuous wire movement and narrow kerf of our machines allow for efficient cutting, reducing production bottlenecks and enabling high-volume manufacturing.

3. Versatility for a Range of Materials

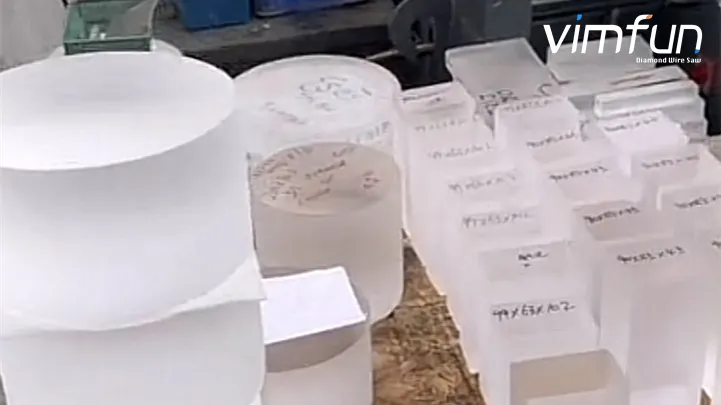

The diverse materials used in 5G and IoT components require a cutting solution that can handle different levels of hardness and brittleness. VIMFUN’s diamond wire cutting machines are versatile enough to cut a wide variety of materials, including:

- Sapphire: Used in optical windows and substrates for 5G antennas.

- Quartz: Essential for frequency control devices and sensors in IoT applications.

- Silicon carbide (SiC): A key material for power electronics in 5G base stations and IoT devices.

This versatility makes our machines a one-stop solution for manufacturers working across multiple applications in the 5G and IoT industries.

4. Sustainability in Component Production

As the demand for 5G and IoT components grows, so does the need for sustainable manufacturing practices. Diamond wire cutting technology supports sustainability by minimizing material waste and reducing energy consumption compared to traditional methods.

For example, the narrow kerf of our cutting machines ensures that less material is wasted during the production of high-value components. Additionally, the energy-efficient design of our equipment helps manufacturers lower their carbon footprint while maintaining high productivity. These features align with the broader industry push toward more eco-friendly production practices.

Case Study: Enabling High-Precision Sapphire Cutting for 5G Antennas

One of our clients, a leading manufacturer of 5G antenna components, faced challenges in achieving the precision required for their sapphire substrates. Traditional cutting methods resulted in rough edges and inconsistencies, leading to higher rejection rates and increased costs.

By switching to VIMFUN’s diamond wire cutting technology, the client was able to:

- Achieve smoother cuts with tight tolerances, ensuring the substrates met the performance requirements for high-frequency antennas.

- Reduce material waste by 30%, lowering production costs.

- Increase throughput by 40%, enabling them to meet growing demand for their components.

This transformation not only improved the client’s production efficiency but also helped them maintain a competitive edge in the rapidly expanding 5G market.

The Future of Diamond Wire Cutting in 5G and IoT

As 5G and IoT technologies continue to evolve, the demand for high-precision components will only grow. Diamond wire cutting is uniquely positioned to meet these demands, offering a combination of precision, efficiency, and sustainability that other cutting methods struggle to match.

At VIMFUN, we are committed to supporting manufacturers in these industries by providing cutting solutions that keep pace with technological advancements. Whether it’s cutting sapphire for optical components, silicon carbide for power electronics, or quartz for sensors, our machines are designed to deliver the precision and reliability needed for next-generation technologies.

Conclusion: A Cutting-Edge Solution for the Future of Connectivity

The rise of 5G and IoT represents a new frontier in technology, and manufacturers must adopt advanced solutions to stay competitive. VIMFUN’s diamond wire cutting technology is helping companies meet the challenges of this exciting era by providing precise, efficient, and sustainable cutting solutions for the most demanding applications.

If your business is involved in the production of 5G or IoT components, VIMFUN can help you achieve the precision and efficiency needed to succeed in this fast-moving market. Contact us today to learn how our cutting solutions can transform your manufacturing processes and position your company for the future.