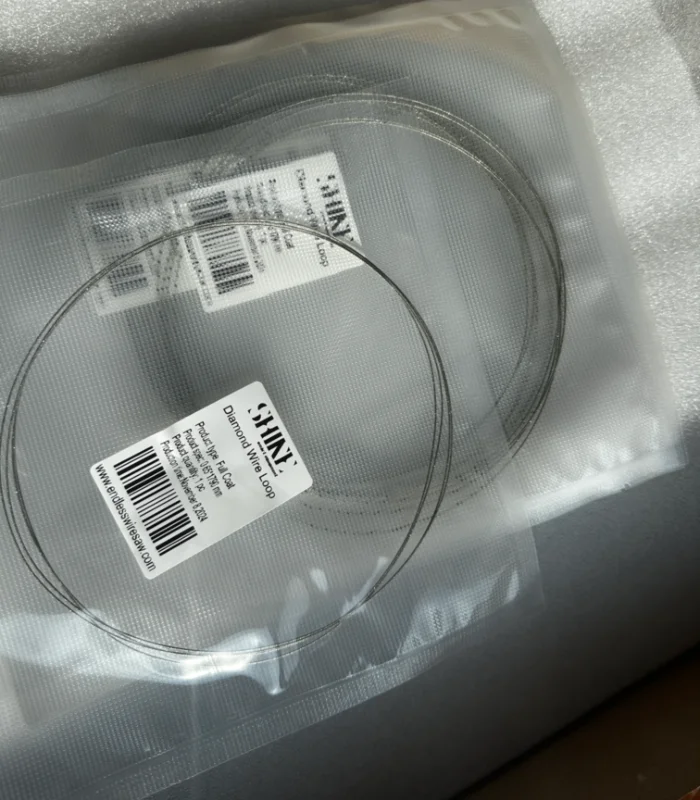

Full coated diamond wire loops are advanced cutting tools designed for precision, speed, and durability in industrial cutting applications. These closed-loop wires are fully coated with high-quality diamond particles, providing exceptional cutting efficiency and an extended lifespan.

Diamond wire cutting stands out from traditional cutting tools due to its ability to change cutting direction by 180 degrees, making it highly suitable for cutting intricate and precise contours. This advanced cutting method offers several key advantages:

- Superior Surface Quality: Achieves smooth and flawless cutting surfaces, eliminating the need for additional post-processing.

- Narrow Kerf: Produces minimal kerf width, significantly reducing material waste.

- High Cutting Speed: Operates at high linear speeds (up to 80 m/s), greatly improving cutting efficiency.

- Wide Range of Applications: Ideal for cutting hard and brittle materials, such as optical glass, silicon wafers, sapphire, quartz, and more.

The unique features of diamond wire cutting make it a preferred solution for industries requiring precision and efficiency, including semiconductor manufacturing, optoelectronics, and high-performance material processing.

Key Features:

-

High Breaking Strength of the Base Wire; The wire's core material is engineered for exceptional breaking strength, ensuring that the cutting wire is resistant to snapping, even under high tension, providing reliable and stable performance.

-

Premium Diamond Quality: The diamonds used in the coating are of superior quality, offering extreme sharpness and cutting efficiency, which translates to faster and more precise cuts.

-

Advanced Coating Technology: State-of-the-art coating techniques firmly bond the diamond particles to the wire, minimizing the risk of diamond detachment and ensuring long-lasting cutting performance.

-

Excellent Coating Uniformity: The coating is applied with meticulous consistency, resulting in smooth cutting surfaces without defects or unevenness, which is critical for high-precision applications.

-

Customizable Wire Lengths: The wire loops can be tailored to specific length requirements, offering flexibility to meet the diverse needs of various industries and equipment setups.

Reviews

Clear filtersThere are no reviews yet.