As the global focus on climate change intensifies, industries across the world are striving to adopt more sustainable practices and achieve net-zero emissions. Manufacturing companies are under increasing pressure to reduce their environmental footprint while maintaining productivity and quality. In this context, innovative technologies like diamond wire cutting are playing a pivotal role in helping manufacturers achieve their sustainability goals.

At VIMFUN, we are proud to support our clients in their journey toward net-zero manufacturing by offering cutting solutions that minimize waste, reduce energy consumption, and align with the principles of sustainable production. In this article, we’ll explore how our diamond wire cutting technology contributes to more sustainable manufacturing practices and helps businesses meet the challenges of today’s environmentally conscious marketplace.

What Is Net-Zero Manufacturing?

Net-zero manufacturing refers to production processes that emit no more greenhouse gases than they remove from the atmosphere. Achieving this balance requires a combination of strategies, including:

- Reducing energy consumption through more efficient technologies.

- Minimizing material waste by optimizing production processes.

- Adopting renewable energy sources to power manufacturing operations.

- Recycling and reusing materials to close the loop on production waste.

By integrating these principles, manufacturers can significantly reduce their carbon footprint while contributing to a more sustainable future. VIMFUN’s diamond wire cutting technology supports these efforts by providing precise, efficient, and environmentally friendly cutting solutions.

How Diamond Wire Cutting Supports Net-Zero Goals

1. Reducing Material Waste

Traditional cutting methods, such as sawing or abrasive cutting, often generate significant waste due to their wide kerf and lack of precision. This is especially problematic when working with expensive materials like sapphire, quartz, and silicon carbide, where every millimeter counts.

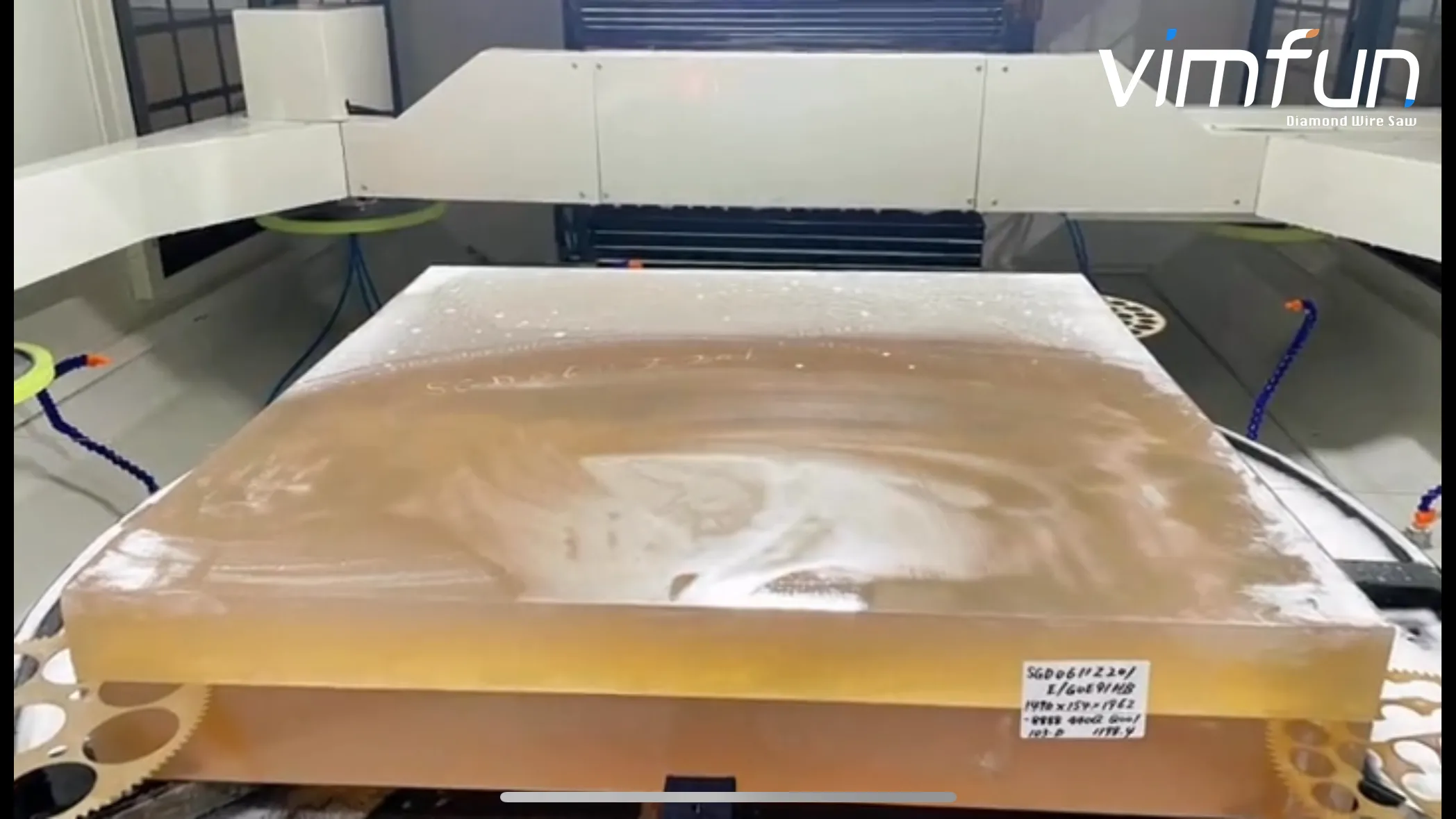

VIMFUN’s diamond wire cutting machines produce a narrow kerf, ensuring that less material is wasted during the cutting process. This not only lowers production costs but also reduces the need for additional raw materials, contributing to a more sustainable and efficient production cycle.

For example, in the production of semiconductor wafers, our technology enables manufacturers to maximize material utilization, reducing waste by up to 30% compared to traditional methods. This improved efficiency aligns directly with net-zero manufacturing objectives by minimizing resource consumption and lowering the overall environmental impact.

2. Enhancing Energy Efficiency

Energy consumption is a major contributor to greenhouse gas emissions in the manufacturing sector. Traditional cutting technologies, such as laser cutting or electrical discharge machining (EDM), often require high levels of energy to operate effectively.

In contrast, diamond wire cutting is a highly energy-efficient process. The precision of the diamond-coated wire allows for faster, cleaner cuts with minimal power consumption. Additionally, our machines are designed with advanced energy-saving features, enabling manufacturers to reduce their energy usage without compromising on performance or quality.

By adopting VIMFUN’s cutting solutions, companies can significantly lower their energy consumption, contributing to both cost savings and a reduced carbon footprint. This energy efficiency is particularly beneficial for businesses aiming to align their operations with international sustainability standards.

3. Supporting Material Recycling and Reuse

The circular economy, a key component of sustainable manufacturing, focuses on minimizing waste by recycling and reusing materials. Diamond wire cutting technology supports this approach by enabling cleaner cuts that preserve the integrity of leftover materials.

For instance, when cutting optical materials or piezoelectric ceramics, the narrow kerf and precision of our machines ensure that the by-products generated during the cutting process can be easily collected and reused. This not only reduces waste but also extends the life cycle of valuable resources, further supporting net-zero goals.

4. Minimizing Environmental Impact

The diamond wire cutting process generates less heat and noise compared to traditional cutting methods, resulting in a cleaner and quieter working environment. This reduction in operational by-products contributes to a healthier workplace while minimizing the environmental impact of manufacturing activities.

Moreover, the durability of our diamond wires means fewer replacements are needed, reducing the overall waste generated by consumables. These benefits make VIMFUN’s cutting solutions a key part of any strategy to achieve sustainable manufacturing and net-zero emissions.

Real-World Applications: Helping Clients Achieve Sustainability

Case Study: Sustainable Cutting for Semiconductor Manufacturing

One of our clients, a global leader in semiconductor manufacturing, was facing challenges in reducing their material waste and energy consumption. By adopting VIMFUN’s diamond wire cutting machines, they were able to:

- Reduce material waste by 35%, thanks to the narrow kerf and high precision of the cutting process.

- Lower energy consumption by 25%, achieving significant cost savings and reducing their carbon footprint.

- Recycle 50% more material, enabling them to integrate more sustainable practices into their production cycle.

This transformation not only helped the client align with net-zero goals but also strengthened their position as an environmentally conscious market leader.

Why Choose VIMFUN for Sustainable Manufacturing?

At VIMFUN, we are committed to helping manufacturers achieve their sustainability goals by providing cutting solutions that are both efficient and environmentally friendly. Our diamond wire cutting technology offers:

- Precision and Efficiency: Minimize waste and maximize productivity with high-precision cutting.

- Energy Savings: Reduce energy consumption with our energy-efficient machines.

- Sustainability: Support material recycling and reuse for a circular manufacturing process.

- Reliability: Durable equipment designed to perform consistently over time.

By choosing VIMFUN, you are not only investing in advanced cutting technology but also contributing to a greener, more sustainable future.

Conclusion: Leading the Way to Net-Zero Manufacturing

Achieving net-zero manufacturing is a challenging but necessary goal for industries worldwide. With VIMFUN’s diamond wire cutting technology, manufacturers can take meaningful steps toward reducing waste, saving energy, and minimizing their environmental impact. Our cutting solutions are designed to help businesses align their operations with sustainability standards while maintaining the highest levels of precision and efficiency.

If your company is striving to meet net-zero goals and adopt more sustainable practices, VIMFUN’s cutting solutions are here to help. Contact us today to learn how our technology can transform your production processes and contribute to a more sustainable future.