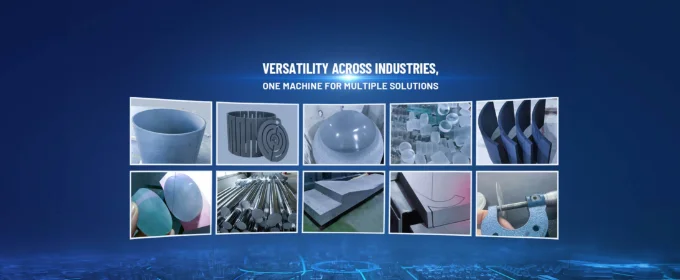

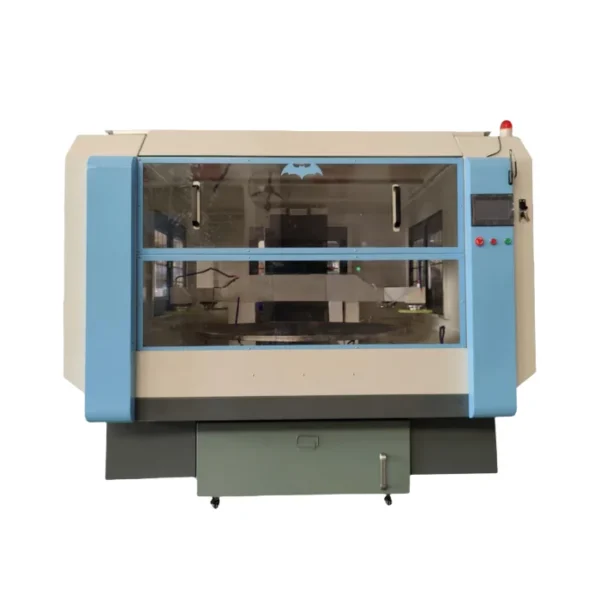

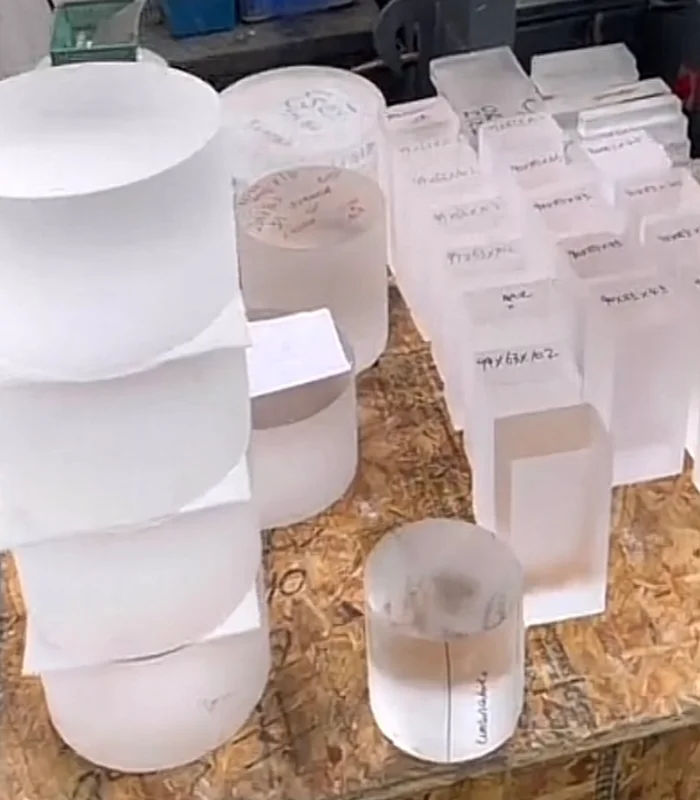

We are a manufacturer of diamond wire cutting equipment. In addition to the listed equipment models, we can also customize machines according to customer requirements. By providing the product dimensions to be cut and the cutting specifications, we can quickly tailor the equipment to meet personalized needs.

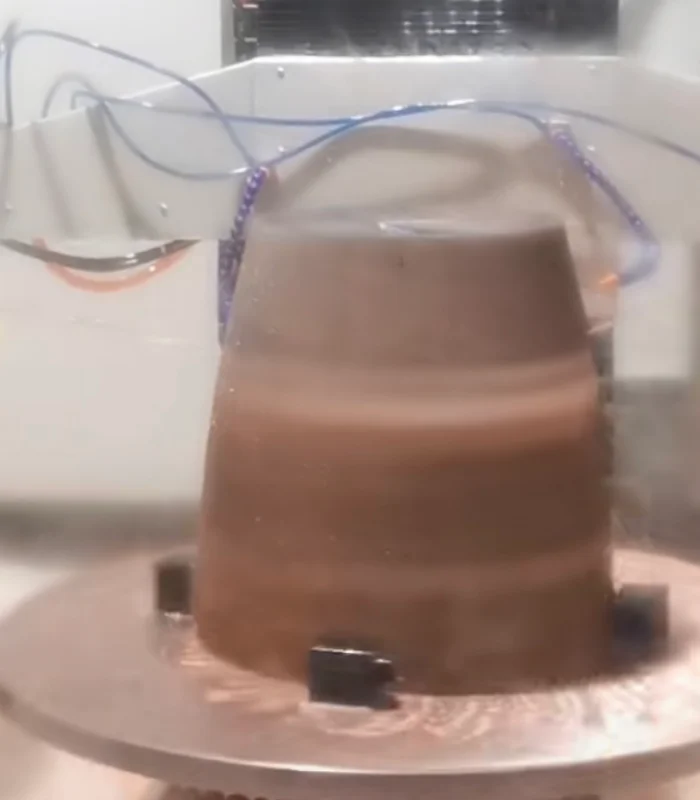

The cutting tool used by our equipment is a diamond wire, which is available in both closed-loop and non-closed-loop types. The equipment structure includes vertical, horizontal, and gantry types. The cutting methods include dry cutting and wet cutting. The equipment functions are categorized into semi-automatic cutting, fully automatic slicing, CNC cutting of external profiles, CNC cutting of internal hole profiles, cutting of taper angles, and multi-wire cutting.

Each model of the listed equipment is available in various sizes, including large, medium, and small, to meet the cutting requirements of different material dimensions.

The wet cutting equipment can also be used for dry cutting. However, if you need to perform water-assisted cutting on a dry cutting machine, please contact us for waterproofing modifications.

The power supply of the equipment can be customized according to customer requirement.

Please contact us before placing an order to ensure that the selected equipment meets your needs.

Large Quartz Components: Used in optical and industrial applications.

K9 Optical Glass: For high-precision large optical parts.

Microcrystalline Glass: Large panels or blocks for scientific and industrial use.

Germanium Crystals: For infrared optics and semiconductor manufacturing.

Large Silicon Rods: For photovoltaic and semiconductor industries.

Reviews

Clear filtersThere are no reviews yet.