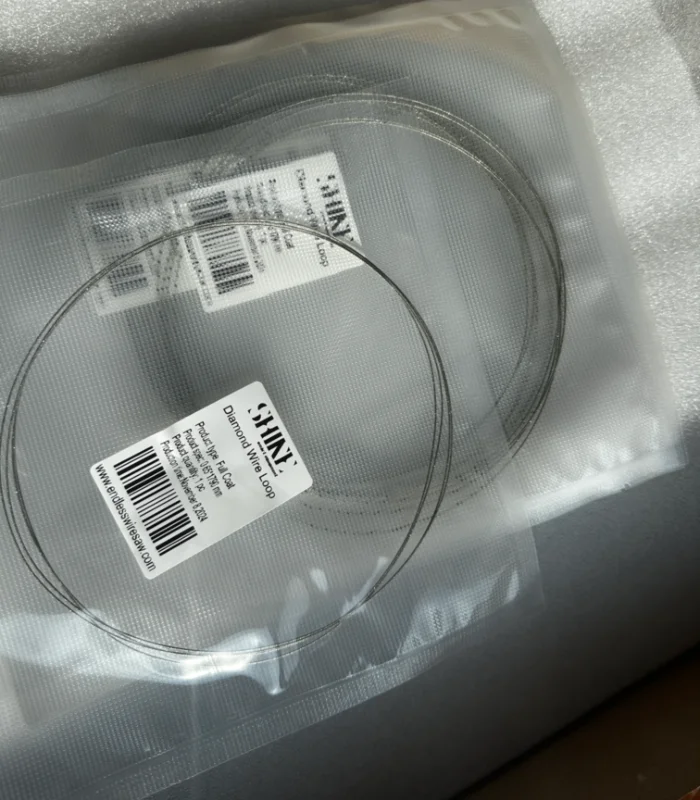

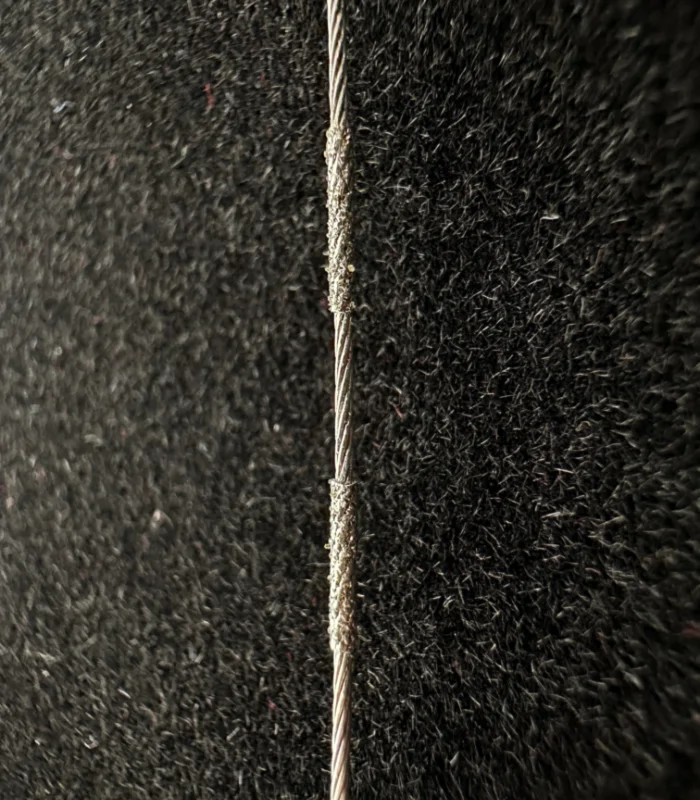

The Segmented Coated Diamond Wire Loop is an advanced version of the first-generation closed-loop diamond wire. Its innovative segmented coating design creates larger chip-clearance spaces, making it highly effective for cutting materials that generate significant debris. This design improves chip removal and enhances heat dissipation during cutting, ensuring smoother and more efficient operation.

With superior durability, the segmented coated diamond wire loop has a cutting lifespan 2 to 3 times longer than traditional fully coated diamond wires, offering excellent performance and cost efficiency for demanding cutting applications.

-

Improved Chip Removal: Segmented coating increases chip-clearance space, optimizing debris removal.

-

Enhanced Heat Dissipation: The design helps maintain lower operating temperatures, reducing wear.

-

Longer Lifespan: Offers 2 to 3 times the cutting life of traditional diamond wires, improving cost-effectiveness.

Reviews

Clear filtersThere are no reviews yet.