Product Overview

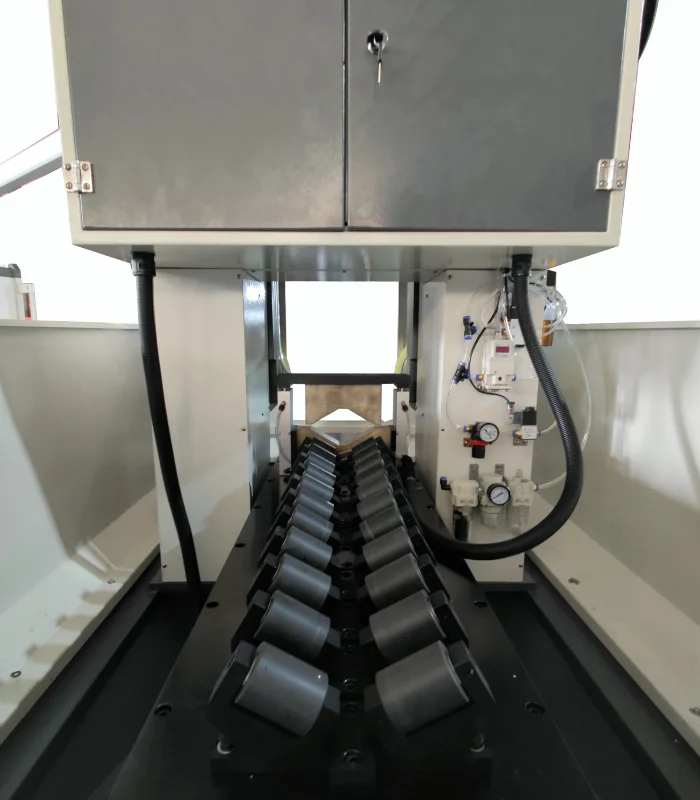

The Silicon Ingot Cropping Machine SGC 30 is a specialized cutting machine designed for processing silicon ingots, commonly used in the semiconductor industry. This machine utilizes an endless diamond wire for efficient and precise cutting. With its fast cutting speed and low edge-chipping rate, the SGC 30 is ideal for cropping the heads and tails of silicon ingots, as well as for sectioning and slicing ingots into wafers. Featuring a gantry-style design with the cutting wire running parallel to the ground, this machine can process silicon ingots up to 12 inches in diameter, with an option available for 18-inch ingots.

Product Details

Key Features

- Single-Wire Cutting System

- The SGC 30 uses a single endless diamond wire for cutting, delivering high precision and excellent surface quality with minimal kerf loss.

- Gantry-Style Structure

- The cutting wire operates parallel to the ground, performing top-to-bottom cuts that provide stable and consistent results.

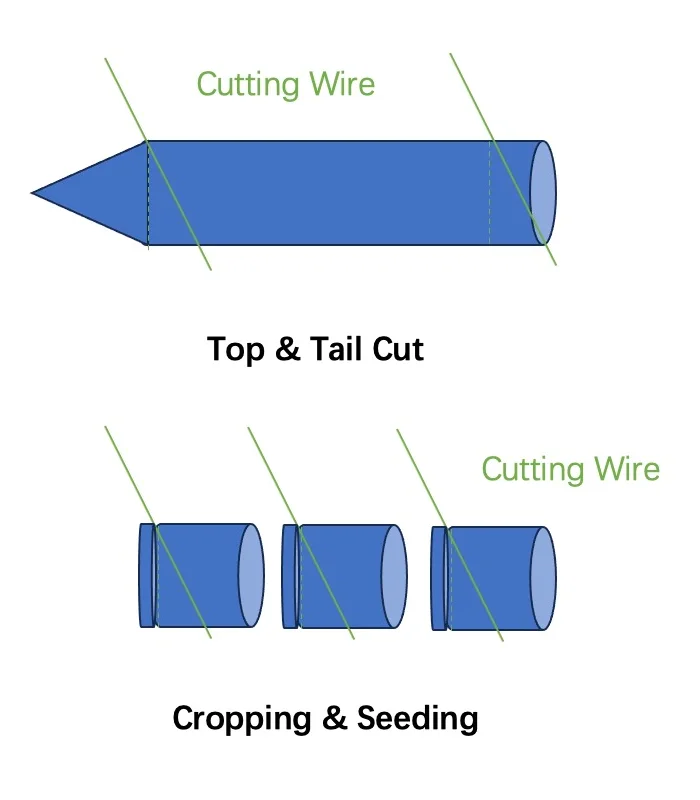

- Automatic Ingot Cropping

- The machine can automatically remove the heads and tails of silicon ingots, improving productivity and reducing manual handling.

- Sectioning and Slicing Capabilities

- In addition to cropping, the SGC 30 can divide ingots into smaller sections or slice them into wafers, offering flexible processing options for various semiconductor applications.

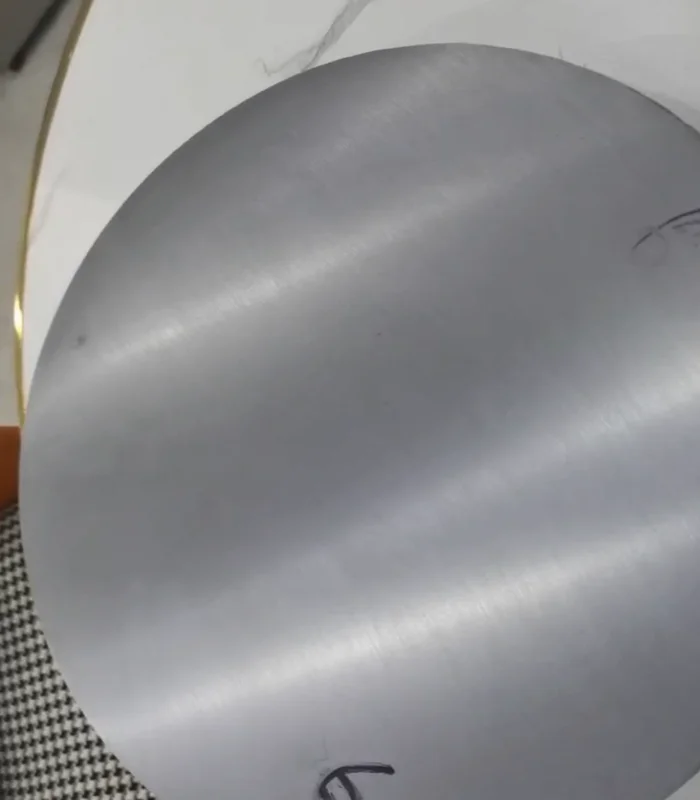

- High Cutting Speed with Low Edge-Chipping

- Fast cutting speeds combined with a low edge-chipping rate ensure clean, precise cuts and higher yield.

- 12-Inch and 18-Inch Models

- The standard model can handle silicon ingots up to 12 inches, with an optional version capable of processing 18-inch ingots to meet larger production requirements.

Advantages

-

Fast and Precise Cutting: Delivers high cutting speeds with excellent precision, minimizing material waste and maximizing yield.

-

Low Edge-Chipping Rate: The advanced cutting technology ensures clean edges with minimal chipping, reducing post-processing needs.

-

Automatic Cropping: Reduces labor requirements by automating the removal of ingot heads and tails, streamlining production.

-

Flexible Processing Options: Capable of cropping, sectioning, and slicing, making it versatile for various semiconductor manufacturing needs.

-

Customizable for Larger Ingot Sizes: Models available for both 12-inch and 18-inch silicon ingots, providing scalability for different production scales.

Applications

The SGC 30 is specifically designed for the processing of silicon ingots in the semiconductor industry, including:

- Ingot Cropping: Perfect for cropping the heads and tails of silicon ingots to prepare them for further processing.

With its advanced cutting capabilities, speed, and versatility, the Silicon Ingot Cropping Machine SGC 30 is the perfect solution for efficient and precise silicon ingot processing in the semiconductor industry.

Reviews

Clear filtersThere are no reviews yet.