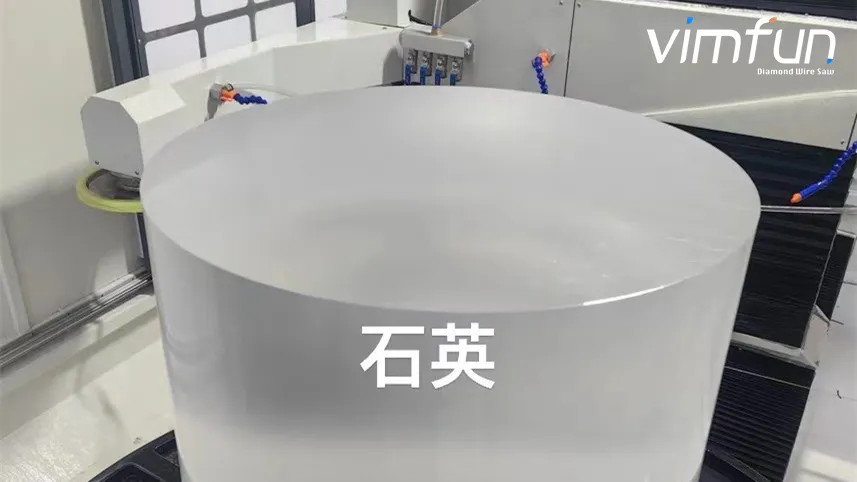

Quartz, a material known for its exceptional stability, optical clarity, and electrical properties, is a cornerstone in high-tech industries. From precision sensors and oscillators to optical components, quartz plays a vital role in a wide range of applications. However, cutting and shaping quartz to meet the strict requirements of these applications poses significant challenges.

In this article, we share the story of how VIMFUN’s diamond wire cutting technology helped a leading manufacturer optimize their quartz cutting process. By adopting our innovative solutions, the company was able to achieve unparalleled precision, reduce material waste, and improve overall efficiency.

The Customer’s Challenge: Precision Meets Complexity

Our client, a manufacturer specializing in quartz-based components for optical systems and high-frequency electronics, faced several issues with traditional cutting methods:

- Inconsistent Precision: Quartz components require extremely tight tolerances to function effectively in advanced devices. However, the client’s previous cutting methods often resulted in uneven edges and variations in dimensions, leading to high rejection rates.

- Material Waste: Traditional sawing techniques produced a wide kerf, wasting significant amounts of raw quartz material. For a high-value material like quartz, this waste was both costly and unsustainable.

- Slow Production Speeds: The existing cutting equipment operated at slower speeds, limiting the client’s ability to meet rising demand for quartz components in industries like telecommunications and aerospace.

- Post-Processing Requirements: Rough cuts required extensive polishing and finishing, adding extra steps to the production process and increasing lead times.

Faced with these challenges, the client turned to VIMFUN for a cutting solution that could address these issues while improving their overall production capabilities.

The VIMFUN Solution: Precision and Efficiency Redefined

1. Precision Cutting with Minimal Tolerance

VIMFUN’s diamond wire cutting machines are designed to achieve micron-level precision, making them ideal for cutting quartz. The diamond-coated wire slices through the material cleanly, leaving smooth edges and consistent dimensions. With this technology, the client was able to meet the stringent tolerances required for their high-tech applications, reducing rejection rates and ensuring product quality.

2. Narrow Kerf for Reduced Material Waste

One of the standout features of our cutting technology is the narrow kerf, which minimizes material loss during the cutting process. By reducing waste by up to 30%, the client was able to maximize the yield from their quartz stock, lowering production costs and improving sustainability.

3. Increased Cutting Speed and Throughput

Our machines operate at significantly faster speeds compared to traditional cutting methods, enabling higher production rates without sacrificing quality. For the client, this meant they could scale their operations to meet the growing demand for quartz components while maintaining their commitment to precision and efficiency.

4. Superior Surface Finish

The smooth cuts produced by diamond wire cutting eliminated the need for extensive post-processing. By reducing polishing and finishing steps, the client was able to shorten their production cycle and deliver products to market faster.

Applications of Quartz in High-Tech Industries

Quartz is an essential material in many advanced technologies, including:

- Optical Components: Used in lenses, prisms, and other devices requiring optical clarity and stability.

- High-Frequency Electronics: Quartz is a key material in oscillators and filters, providing the precision needed for telecommunications and aerospace systems.

- Sensors: Its stability and reliability make it ideal for use in precision sensors, including those in industrial automation and medical devices.

The client’s products are critical to these industries, making the performance and quality of their quartz components non-negotiable. By adopting VIMFUN’s diamond wire cutting technology, they were able to enhance their competitiveness and maintain their reputation as a leader in quartz manufacturing.

Customer Success: Measurable Results

After implementing VIMFUN’s cutting machines, the client achieved remarkable improvements across their operations:

- Rejection Rate Reduced by 50%: The precision of the cuts ensured consistent quality, significantly lowering the number of defective components.

- Material Waste Reduced by 30%: The narrow kerf maximized the use of raw quartz material, leading to substantial cost savings.

- Production Speed Increased by 40%: Faster cutting speeds enabled the client to handle higher volumes and meet tight delivery schedules.

- Post-Processing Time Reduced by 35%: Smooth cuts minimized the need for extensive polishing, saving time and resources.

Client Feedback: A Transformative Experience

Here’s what the client had to say about their experience with VIMFUN’s diamond wire cutting technology:

“The transition to VIMFUN’s diamond wire cutting machines has revolutionized our quartz manufacturing process. The precision, efficiency, and material savings have exceeded our expectations, allowing us to not only meet but surpass our production goals. This technology has been a game-changer for our business.”

Why Choose VIMFUN for Quartz Cutting?

VIMFUN’s diamond wire cutting machines are engineered to meet the unique challenges of cutting hard and brittle materials like quartz. Key advantages include:

- High Precision: Achieve tight tolerances and defect-free cuts for high-performance applications.

- Efficiency: Reduce waste and increase throughput with faster cutting speeds.

- Versatility: Handle a range of materials, including quartz, sapphire, and silicon carbide.

- Reliability: Durable machines designed to deliver consistent results in demanding production environments.

With our cutting solutions, manufacturers can enhance their operations, improve product quality, and reduce costs—all while meeting the demands of high-tech industries.

Conclusion: Setting a New Standard in Quartz Cutting

Quartz is an indispensable material in today’s high-tech world, and its production requires cutting solutions that deliver precision, efficiency, and reliability. VIMFUN’s diamond wire cutting technology is redefining what’s possible in quartz cutting, helping manufacturers achieve their goals and drive innovation.

If you’re looking to optimize your quartz manufacturing process, contact VIMFUN today to learn how our cutting solutions can transform your production capabilities and help you stay ahead in the competitive high-tech market.