Precision is the foundation of success in industries such as semiconductors, optoelectronics, and advanced ceramics manufacturing. Whether you’re cutting sapphire, silicon carbide, or quartz, achieving the perfect balance of speed, accuracy, and efficiency is crucial for producing high-quality components. At VIMFUN, our diamond wire cutting machines are engineered to meet these demands, combining cutting-edge design with advanced technology to deliver unmatched precision and reliability.

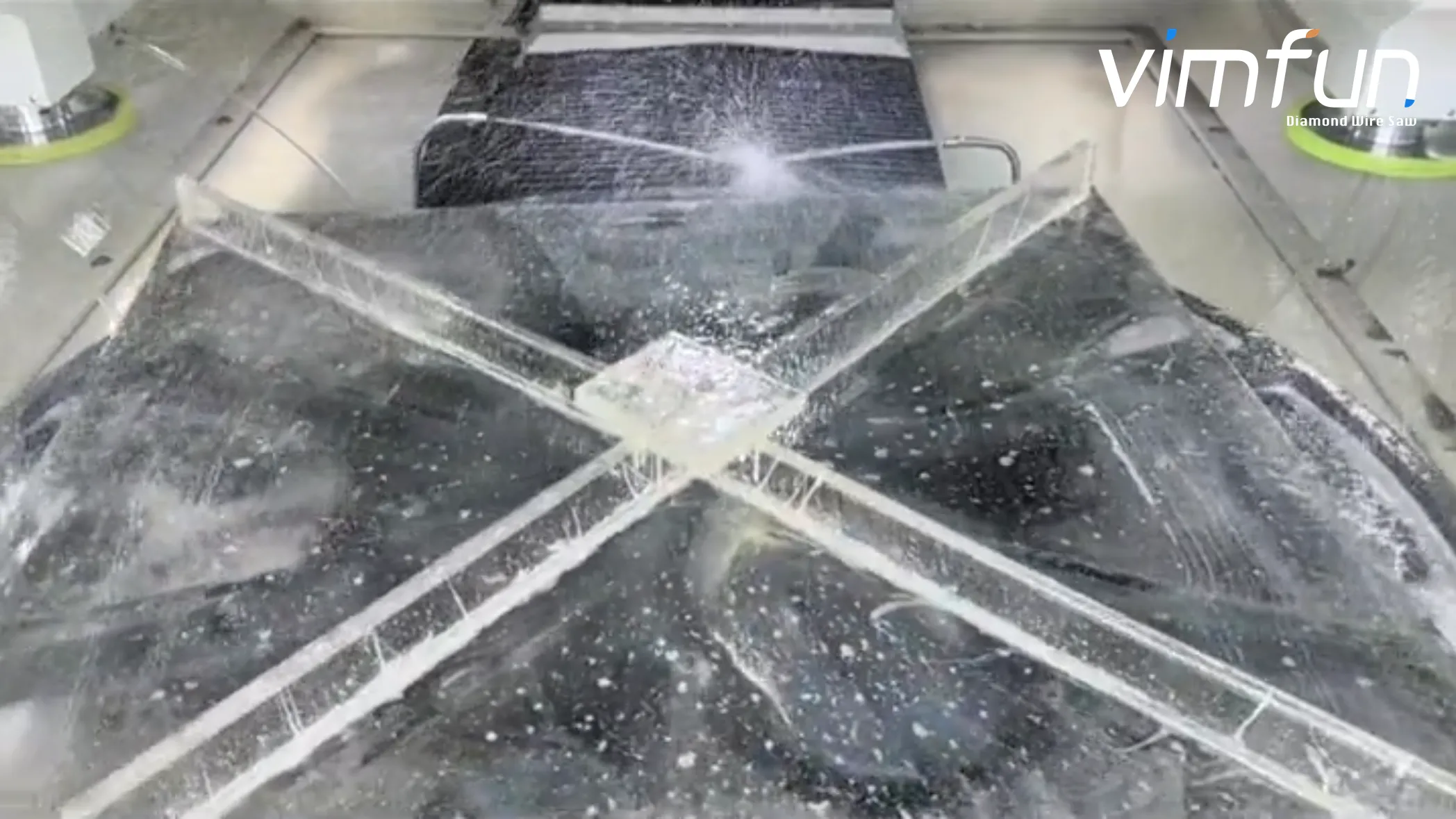

In this article, we’ll break down the key features that make VIMFUN’s diamond wire cutting machines the preferred choice for manufacturers around the world. Through diagrams and video demonstrations, we’ll explore how these features work together to deliver superior results across a range of applications.

1. Advanced Wire Tensioning System

One of the critical elements of precision cutting is maintaining consistent wire tension. Our machines are equipped with an advanced wire tensioning system that ensures the diamond wire remains taut throughout the cutting process. This feature provides several key benefits:

- Consistent Cutting Quality: Even tension reduces the risk of uneven cuts or wire breakage, ensuring smooth and precise results.

- Extended Wire Life: By minimizing stress on the wire, the tensioning system helps extend its operational lifespan, lowering overall maintenance costs.

- High Speed and Stability: Stable wire tension allows for faster cutting speeds without compromising accuracy.

Our video demonstration showcases the tensioning system in action, highlighting its ability to handle even the most delicate materials like sapphire wafers or quartz substrates.

2. Narrow Kerf Technology

VIMFUN’s diamond wire cutting machines are designed to produce a narrow kerf, which minimizes material loss during the cutting process. This feature is especially important when working with high-value materials such as silicon carbide or piezoelectric ceramics.

Benefits of the narrow kerf include:

- Maximized Material Yield: Less material is wasted, enabling manufacturers to extract more usable components from each raw material block.

- Cost Efficiency: Reducing material waste directly translates to lower production costs and higher profitability.

- Enhanced Sustainability: By minimizing waste, the cutting process becomes more environmentally friendly, supporting sustainable manufacturing practices.

Our diagrams illustrate how the narrow kerf technology works, demonstrating its impact on material utilization and efficiency.

3. Precision Control System

To achieve micron-level accuracy, our machines feature an advanced precision control system. This system uses state-of-the-art sensors and software to monitor and adjust the cutting process in real time. Key advantages include:

- Accurate Cuts: Automated adjustments ensure that each cut meets the exact specifications, even when dealing with complex geometries or varying material densities.

- Defect-Free Results: The precision control system eliminates issues such as cracks, chips, or uneven surfaces, reducing the need for post-processing.

- User-Friendly Operation: Intuitive controls and customizable settings make it easy for operators to achieve optimal results with minimal training.

A short video included in this article demonstrates how our precision control system seamlessly integrates into the cutting process, showcasing its role in producing high-quality optical components.

4. Modular and Durable Design

Our diamond wire cutting machines are built with a modular design, allowing for easy maintenance and customization. This design philosophy not only reduces downtime but also ensures that the machines can be adapted to meet the specific needs of different industries.

Key aspects of the modular design include:

- Easy Component Replacement: Critical parts, such as guides and pulleys, can be quickly replaced without disrupting production schedules.

- Scalability: The modular design allows manufacturers to upgrade or expand their machines as their production needs evolve.

- Built to Last: Constructed with high-strength steel frames and wear-resistant components, our machines are engineered for durability, even under heavy-duty operating conditions.

Our video content includes a behind-the-scenes look at the production and assembly process, highlighting the quality and craftsmanship that go into every machine.

5. Energy-Efficient Operations

Energy efficiency is a growing priority for manufacturers seeking to reduce costs and minimize their environmental impact. VIMFUN’s diamond wire cutting machines are designed to operate with minimal energy consumption while maintaining exceptional performance.

Features that enhance energy efficiency include:

- Optimized Motor Systems: Advanced motors deliver high power with low energy input, reducing overall electricity usage.

- Cooling Systems: Integrated cooling systems prevent overheating, ensuring that the machines run efficiently without consuming excessive power.

- Reduced Operational Costs: Lower energy usage translates to cost savings over the long term, making our machines an economical choice for high-volume production.

Real-World Applications of VIMFUN’s Cutting Technology

The advanced features of VIMFUN’s diamond wire cutting machines make them ideal for a variety of applications:

- Semiconductors: Precision cutting of silicon carbide for high-performance power devices.

- Optoelectronics: Smooth, crack-free cuts for sapphire wafers used in LEDs and laser systems.

- Advanced Ceramics: Accurate shaping of piezoelectric ceramics for sensors and actuators.

Our machines have been successfully deployed in industries worldwide, helping manufacturers improve their production processes and meet the demands of modern markets.

Customer Feedback: The VIMFUN Difference

Here’s what one of our satisfied customers had to say about our diamond wire cutting machines:

“The precision and efficiency of VIMFUN’s diamond wire cutting technology have transformed our production line. The modular design and intuitive controls make it easy to adapt the machines to our needs, and the consistent cutting quality has helped us maintain our reputation for excellence.”

Conclusion: Precision Engineered for Success

At VIMFUN, we understand that precision and reliability are non-negotiable in today’s manufacturing landscape. Our diamond wire cutting machines combine state-of-the-art features with robust design to deliver exceptional performance, helping manufacturers achieve their goals with confidence.

If you’re ready to elevate your cutting capabilities, contact VIMFUN today to learn more about how our machines can support your production needs. From sapphire wafers to advanced ceramics, our technology is designed to help you cut smarter, faster, and better.