Product Overview

The Contour Cut Diamond Wire Saw SGI 20 is a horizontal CNC-controlled cutting machine specifically designed for precision contour cutting. With its cutting wire aligned parallel to the ground, this machine delivers high accuracy, fast cutting speeds, and unmatched operational convenience. Its horizontal structure ensures that cut materials remain stable and do not fall, preventing damage to the product and simplifying the workflow. Capable of processing materials up to 200 x 200 x 200 mm in size, the SGI 20 is highly versatile and ideal for applications in research laboratories, optical industries, and advanced material processing.

Product Details

Key Features

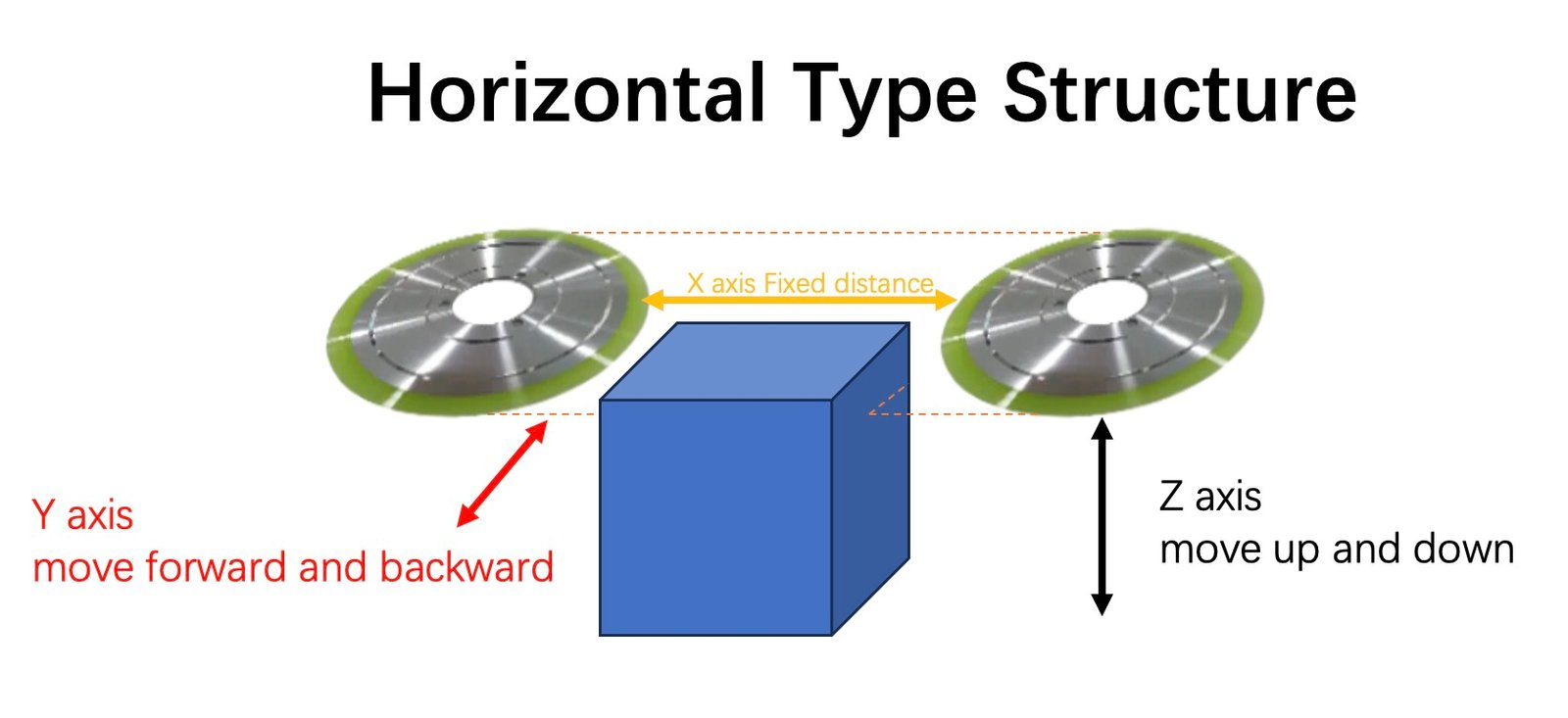

- Horizontal Cutting Structure

- The cutting wire operates parallel to the ground, ensuring stability and preventing materials from falling after cutting. This minimizes product damage and simplifies handling.

- Precision CNC Control

- Equipped with a CNC system for high-accuracy contour cutting, enabling complex shapes and designs with exceptional precision.

- High Cutting Speed

- Optimized for efficiency, the SGI 20 offers fast cutting speeds without compromising on quality.

- Versatile Material Compatibility

- Processes a wide range of hard and brittle materials, including optical glass, alumina, silicon carbide, and magnetic materials.

- Compact and Convenient Operation

- Designed for ease of use, with a small footprint suitable for research labs, R&D facilities, and production workshops.

Advantages

-

High Precision: Delivers clean and accurate cuts for contour shaping of delicate materials.

-

Simplified Workflow: Horizontal structure eliminates product falling, reducing handling effort and risk of damage.

-

Fast and Efficient: Achieves high-speed cutting for improved productivity.

-

Wide Applicability: Suitable for multiple industries and materials, from optical components to semiconductor substrates.

-

User-Friendly Operation: Easy setup and intuitive controls make it ideal for small-scale production and research environments.

Applications

The SGI 20 is ideal for cutting:

- Optical Materials: Quartz, K9 glass, and other precision optical glass.

- Advanced Ceramics: Alumina and silicon carbide components.

- Semiconductor Materials: Silicon wafers and substrates.

- Magnetic Materials: High-precision contour cutting for industrial applications.

- Research and Laboratory Work: Perfect for R&D facilities requiring precision cutting of complex shapes and delicate materials.

With its advanced CNC control, horizontal cutting structure, and high versatility, the Contour Cut Diamond Wire Saw SGI 20 provides the perfect solution for precision contour cutting across multiple industries and applications.

Reviews

Clear filtersThere are no reviews yet.