Product Overview

The Cutting Wire Saw Machine SGSM 40 is a gantry-style cutting solution equipped with an advanced oscillation (swing) function. This innovative feature allows the cutting wire to oscillate during the top-to-bottom cutting process, with the amplitude freely adjustable to suit specific materials and requirements. Designed to handle ultra-hard materials such as alumina, sapphire, and silicon carbide, the SGSM 40 delivers faster cutting speeds, smoother surfaces, and exceptional precision.

Product Details

Key Features

Gantry-Style Structure

- The cutting wire operates parallel to the ground, performing stable, top-to-bottom cuts, ensuring material stability on the work platform.

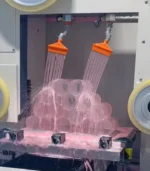

Advanced Oscillation Function

- The cutting wire oscillates during the cutting process, with customizable swing amplitude. This reduces cutting resistance, improves speed, and enhances the surface finish.

High Cutting Precision

- The oscillation feature, combined with the gantry-style design, ensures high accuracy and smooth, chip-free cutting surfaces.

Adjustable Parameters

- Operators can freely set oscillation amplitude and other cutting parameters, allowing optimization for various ultra-hard materials.

Optimized for Ultra-Hard Materials

- Specially designed to process materials like alumina, sapphire, and silicon carbide with superior efficiency and quality.

Advantages

-

Faster Cutting Speeds: Oscillation reduces friction and enhances cutting efficiency, saving time on challenging materials.

-

Smoother Surface Finish: The oscillation motion minimizes surface roughness, delivering polished cuts without the need for secondary processing.

-

Versatile Operation: Customizable oscillation settings allow users to adapt to different material types and thicknesses.

-

Material Stability: The top-to-bottom cutting method keeps the workpiece secure on the platform, ensuring precise and consistent results.

-

User-Friendly Design: Intuitive controls and adjustable parameters make operation simple and efficient.

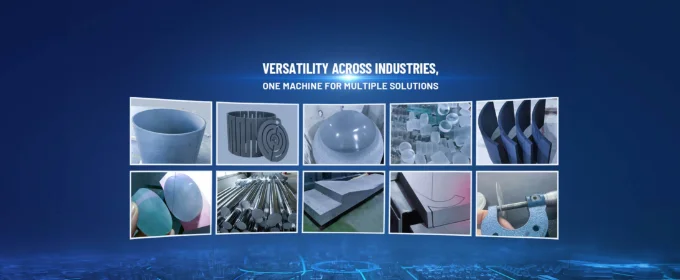

Applications

The SGSM 40 is ideal for cutting ultra-hard and brittle materials, including:

- Alumina (Aluminum Oxide): For ceramics and industrial components.

- Sapphire: Used in optics, electronics, and watch components.

- Silicon Carbide (SiC): For semiconductor wafers, ceramics, and industrial applications.

With its innovative oscillation function, robust gantry-style design, and outstanding precision, the Cutting Wire Saw Machine SGSM 40 is the perfect solution for manufacturers seeking to optimize the cutting of ultra-hard materials with speed, efficiency, and superior surface quality.

Reviews

Clear filtersThere are no reviews yet.